|

|

|

|

|

manufacturer of high quality Tube Fittings That's |

|

|

|

|

|

|

|

|

|

SINGLE FERRULE BITE TYPE AS PER DIN 2353 -ISO 8434-1

|

TWIN FERRULE TYPE AS PER UNF TYPE |

ADAPTOR FITTINGS AS PER BSP /NPT /UNF |

|

|

|

|

SOCKET WELD TYPE AS PER CODE 61 & 62 |

JIC 37 0° FLARE TYPE AS PER ISO 8434-2 |

WELD NIPPLE TYPE AS PER DIN 2353 -ISO -8434-4 |

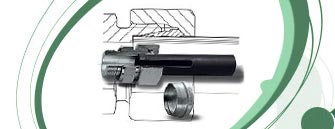

SINGLE FERRULE BITE TYPE FITTINGS |

DIN-2353 |

|

These

Single Ferrule Bite Type Fittings are the most widely used bite type

fittings in the world. These Single Ferrule Bite Type Fittings are flareless

bite type metric fittings that consists of a body, progressive ring

(ferrule) and nut. On assembly, two cutting edges of the ferrule “bite”

into the outer surface of the tube ensuring the necessary holding power for

high operating pressures.

These

Single Ferrule Bite Type Fittings are the most widely used bite type

fittings in the world. These Single Ferrule Bite Type Fittings are flareless

bite type metric fittings that consists of a body, progressive ring

(ferrule) and nut. On assembly, two cutting edges of the ferrule “bite”

into the outer surface of the tube ensuring the necessary holding power for

high operating pressures.

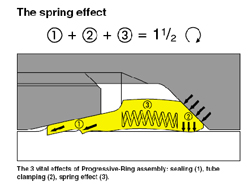

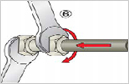

Working Principle |

|

When

the Coupling Nut is progressively tightened it makes the Progressive Ring to

move on to the tube which subsequently makes two bites into the outside

diameter of the pipe, thereby forming a visible collar of material at 1,

ensuring a strong, reliable, high degree of safety and permanent sealing due

to the outstanding construction & design of our progressive ring.

When

the Coupling Nut is progressively tightened it makes the Progressive Ring to

move on to the tube which subsequently makes two bites into the outside

diameter of the pipe, thereby forming a visible collar of material at 1,

ensuring a strong, reliable, high degree of safety and permanent sealing due

to the outstanding construction & design of our progressive ring. |

|

|

|

HEAVY SERIES COUPLING |

LIGHT SERIES COUPLING |

VERY LIGHT SERIES COUPLING |

Our Strength & Support |

|

|

|

|

|

|

FACTORY SET UP |

TECHNICAL DATA SHEET |

ASSEMBLY DATA SHEET |

TIGHTENING TORQUE |

Fittings Accessories |

|

|

|

|

|

|

NUT - N |

SINGLE CUTTING RING - F |

SOFT SEALING CUTTING RING -DAZ |

WELD NIPPLE - WNO |

Tube to Tube Fittings |

|

|

|

|

|

|

EQUAL UNION - G |

REDUCING UNION COUPLING - GR |

EQUAL ELBOW - W |

EQUAL TEE - T |

|

|

|

|

|

EQUAL KROSS - K |

BULKHEAD UNION - SV |

BULKHEAD ELBOW - WSV |

Tube toTubeSwievel Type |

|

|

|

|

|

|

SWIEVEL ELBOW -EVW / EW |

SWIEVEL BRANCH TEE - EVT /ET |

SWIEVEL RUN TEE - EVT / ET |

TUBE END REDUCER -KOR |

Tube to Female Port |

|

|

|

|

|

|

MSC - BSPP - O RING SEALING |

MSC - ED |

MSC - BSPP - METAL SEALING |

RI - MALE x FEMALE |

|

|

|

|

|

ELBOW - LOCK NUT TYPE |

RUN TEE -LOCK NUT TYPE |

SWIEVEL ELBOW -BSPP- PMC -NR |

GAUGE ADAPTOR |

Banjo Fittings |

|

|

|

|

|

|

BANJO ELBOW - SINGLE BOLT |

BANJO ELBOW - THROTTLE FREE |

MALE ELBOW - BSP /NPT /METRIC |

BRANCH TEE |

Weld Nipple Fitting |

|

|

Weld Nipple fittings Principle :- weld nipple fittings with an O-ring seal between weld nipple and fitting body give impressive tear out resistance and sealing integrity. Weld nipples SKA conform with DIN 3865 form A. Fitting bodies and nuts are fully interchangeable for weld nipple and for 2/progressive ring fittings of the same series and external tube diameter. Materials and surface protection: Steel phosphated and oiled, O-ring of NBR (e.g. Perbunan). Stainless steel 1.4571, O-ring of FPM (e.g. Viton) Welding suitability and weldability Weld nipples, tube bend weld nipples and ASK types made of steel are weldable according. to usual techniques. Types made of 1.4571 (stainless) are suitable for arc welding. The welding filler should be selected in accordance with DIN 8556 part 1 with consideration of the type of application and the welding technique. Tube recommendation We recommend the use of tubes in steel and stainless steel as illustrated in this catalogue. Nominal Pressure (PN) of complete weld nipple fittings The nominal working pressure (PN) of a complete weld nipple fitting is dependant upon the least rated component, i.e. tube, weld nipple or fitting. The component out of these three with the lowest rated pressure or working pressure determines the nominal pressure (PN) of the complete fitting. |

Permissible temperature range

For weld nipples, tube bends with weld nipples and ASK types of steel with O-rings of 1. NBR (e.g. Perbunan): –35°C to + 100°C 2. FPM (e.g.viton): –25°C to + 200°C without pressure reductions For temperature range and necessary pressure reductions for weld nipples, weld nipple fittings and ASK types of 1.4571, see corresponding page. Fitting assembly 1. Cut off the tube square, deburr and bevel the end of the tube in conformance with DIN 2559. 2. Slide nut onto the weld nipple. 3. Weld nipple to the tube according to normal welding procedure. The tube and nipple must be aligned. Before welding, please remove the nut. 4. Dress the weld on the inside and outside. 5. Fit the O-ring without twisting. The taper, the nut and the cone must all be clean. 6. Oil the nut, taper and cone and thread before assembly 7. Screw on the nut by hand. Fully tighten using a spanner with 1/4 to 1/2 turns. Make sure that the tube with the weld nipple is assembled straight and without in built stress.  |

|

|

|

|

|

WELD ADAPTOR |

WELD ELBOW |

BULKHEAD WELD COUPLING |

WELD NIPPLE |

SOCKET WELD FITTINGS AS PER ASME - 3000 LBS / 6000 LBS |

|

|

|

|

|

|

SOCKET WELD COUPLING |

SOCKET HALF COUPLING |

SOCKET WELD TEE |

3 PIECE UNION -S/W |

|

|

|

|

|

SOCKET WELD GROUP |

SOCKET WELD BLIND CAP |

SOCKET WELD ELBOW |

SOCKET WELD KROSS |

|

|||

|

SOCKET WELD REDUCER |