|

|

|

|

|

manufacturer of high quality Tube Fittings That's |

|

|

|

|

|

TWIN FERRULE BITE TYPE FITTINGS |

|

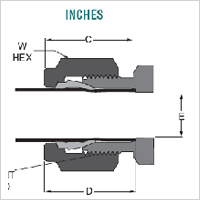

| INCHES | ||||||

| VE-LOCK | D TUBE | |||||

| SIZE | TUBE | STRAIGHT | H | E | INS. | |

| NO. | O.D. | THREAD | C | HEX | DIA | DEPTH |

| 1 | 1/16" | .10-32 | 43 | 5/16" | 52 | 34 |

| 2 | 1/8" | .5/16-20 | 60 | 7/16" | 93 | 50 |

| 3 | 3/16" | .3/8-20 | 64 | 1/2" | 125 | 54 |

| 4 | 1/4" | .7/16-20 | 70 | 9/16" | 187 | 60 |

| 5 | 5/16" | .1/2-20 | 73 | 5/8" | 250 | 64 |

| 6 | 3/8" | .9/16-20 | 76 | 11/16" | 281 | 67 |

| 8 | 1/2" | .3/4-20 | 87 | 7/8" | 406 | 90 |

| 10 | 5/8" | .7/8-20 | 87 | 1" | 500 | 96 |

| 12 | 3/4" | .1-20 | 87 | 1-1/8" | 625 | 96 |

| 14 | 7/8" | .1-1/8-20 | 87 | 1-1/4" | 750 | 1.03 |

| 16 | 1" | .1-5/16-20 | 1.05 | 1-1/2" | 875 | 1.24 |

| 20 | 1.1/4" | .1-5/8-20 | 1.52 | 1-7/8" | 1.09 | 1.61 |

| 24 | 1.1/2" | .1-15/16-20 | 1.77 | 2-1/4" | 1.34 | 1.96 |

| 32 | 2" | .2-5/8-20 | 2.47 | 2-3/4" | 1.81 | 2.65 |

|

|

| MILLIMETERS | ||||||

| VE-LOCK | D TUBE | |||||

| SIZE | TUBE | STRAIGHT | H | E | INS. | |

| NO. | O.D. | THREAD | C | HEX | DIA | DEPTH |

| 2 | 2mm | .5/16-20 | 15.3 | 12 | 1.7 | 12.9 |

| 3 | 3mm | .5/16-20 | 15.3 | 12 | 2.4 | 12.9 |

| 4 | 4mm | .3/8-20 | 16.1 | 12 | 2.4 | 13.7 |

| 6 | 6mm | .7/16-20 | 17.7 | 14 | 4.8 | 15.3 |

| 8 | 8mm | .1/2-20 | 18.6 | 15 | 6.4 | 16.2 |

| 10 | 10mm | .5/8-20 | 19.5 | 18 | 7.9 | 17.2 |

| 12 | 12mm | .3/4-20 | 22 | 22 | 9.5 | 22.8 |

| 14 | 14mm | .7/8-20 | 22 | 24 | 11.1 | 24.4 |

| 15 | 15mm | .7/8-20 | 22 | 24 | 11.9 | 24.4 |

| 16 | 16mm | .7/8-20 | 22 | 24 | 12.7 | 24.4 |

| 18 | 18mm | .1-20 | 22 | 27 | 15.1 | 24.4 |

| 20 | 20mm | .1-1/8-20 | 22 | 30 | 15.9 | 26 |

| 22 | 22mm | .1-1/8-20 | 22 | 30 | 18.3 | 26 |

| 25 | 25mm | .1-5/16-20 | 26.5 | 35 | 21.8 | 31.3 |

| Table 9 | ||||

| Material | Type | ASTM Tubing Spec | Condition | Max.Recommended |

| Hardness | ||||

| stainless Steel | 304,316,316L | ASTM A 269,A 249, | Fully Annealed | 90 Rb |

| A 213,A632 | ||||

| Copper | K or L | ASTM - B75 | Soft Annealed | 60 Max |

| B68, B88 (K or L) | Temper 0 | rockwell 15 T | ||

| Carbon steel | 1010 | SAE -J524b,J525b | Fully Annealed | 72 Rb |

| ASTM-A-179 | ||||

| Aluminum | Alloy 6061 | ASTM B-210 | T6 Temper | 56 Rb |

| Monel | 400 | ASTM B-165 | Fully Annealed | 75 Rb |

| Alloy C-276 | C - 276 | ASTM -B - 622,B - 626 | Fully Annealed | 90 Rb |

| Alloy 600 | 600 | ASTM B -167 | Fully Annealed | 90 Rb |

| Carpenter 20 | 20CB - 3 | ASTM B -468 | Fully Annealed | 90 Rb |

| Titanium | Commercially | ASTM B - 338 | Fully Annealed | 99 Rb |

| Pure Grade 2 | 200 Brinell Typical | |||

|

|

|

|

|

BULKHEAD COUPLING |

EQUAL CROSS |

MALE RUN TEE |

REDUCING UNION COUPLING |

|

|

|

|

|

EQUAL UNION COUPLING |

EQUAL ELBOW COUPLING |

EQUAL UNION COUPLING |

ACCESSORIES |

ADAPTOR THREAD FITTINGS |

|

| THREAD TYPE | STANDARD USED AS | AVAILABLE MOC = MATERIALS | |||

| BSPP | ISO 228 - 1G | STEEL / STAINLESS STEEL / BRASS | |||

| BSPT | ISO 7/1 ,JIS B 0203 | STEEL / STAINLESS STEEL / BRASS | |||

| NPT | SAE J 476 ,ANSI B1.20.3 | STEEL / STAINLESS STEEL / BRASS | |||

| JIC | STEEL / STAINLESS STEEL / BRASS | ||||

| UNF | STEEL / STAINLESS STEEL / BRASS | ||||

| METRIC | DIN 2353 - ISO 8434 -1 | STEEL / STAINLESS STEEL / BRASS | |||

|

|

|

|

|

HEX / HOSE ADAPTOR |

ADAPTOR - MALE x FEMALE(SW) |

ADAPTOR - SW (F) x (F) |

MALE ELBOW |

|

|

|

|

|

FEMALE SWIEVEL ELBOW |

ELBOW - MALE x FEMALE (SW) |

MALE x FEMALE ELBOW |

ELBOW - FEMALE x FEMALE |

|

|

|

|

|

VSTI / ALLEN PLUG WITH ED |

HEX MALE PLUG |

MALE TEE |

FEMALE (SW) TEE |

|

|

|

|

|

BRANCH (SW) TEE |

SWIEVEL FEMALE PLUG |

SOCKET - FEMALE x FEMALE |

RI -REDUCE MALE x FEMALE |

|

|||

|

RI -REDUCE MALE x FEMALE |

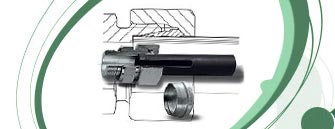

JIC 37 FLARE FITTINGS |

|

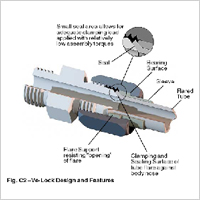

VE-LOCK represents the JIC 37 Flare Fitting concept since year 1994

and the design has since gained worldwide acceptance due to its many

inherent features and customer benefits. Today,the JIC 37 Flare Fitting is

the most widely used fitting in the world. Its appeal is in its simplicity,

compact design, ease of assembly, reliability (single seal), material

availability, adaptability to inch or metric tube, worldwide availability

and acceptance. Further helping its acceptance is its widespread use as a

hose Adaptor.

VE-LOCK represents the JIC 37 Flare Fitting concept since year 1994

and the design has since gained worldwide acceptance due to its many

inherent features and customer benefits. Today,the JIC 37 Flare Fitting is

the most widely used fitting in the world. Its appeal is in its simplicity,

compact design, ease of assembly, reliability (single seal), material

availability, adaptability to inch or metric tube, worldwide availability

and acceptance. Further helping its acceptance is its widespread use as a

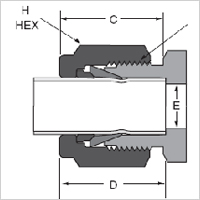

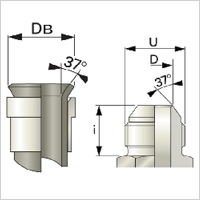

hose Adaptor.  The VE-LOCK (JIC 37 Flare Fitting) design is simple. It uses an

easily produced flare at the tube end to seal and hold fluid under high

pressure. The fitting consists of three pieces : the body, sleeve and nut.

The tube end is flared at a 37 ° angle (74 0 include angle) and held

between the fitting nose (seat) and the sleeve (support) with the nut as

shown in Fig.C2,providing a very effective (single) seal between the fitting

nose and the tube flare.

The VE-LOCK (JIC 37 Flare Fitting) design is simple. It uses an

easily produced flare at the tube end to seal and hold fluid under high

pressure. The fitting consists of three pieces : the body, sleeve and nut.

The tube end is flared at a 37 ° angle (74 0 include angle) and held

between the fitting nose (seat) and the sleeve (support) with the nut as

shown in Fig.C2,providing a very effective (single) seal between the fitting

nose and the tube flare.  The

primary difference between a two -piece flare fitting and the three - piece

design is the flare support sleeve. The support sleeve provides several key

functions:

The

primary difference between a two -piece flare fitting and the three - piece

design is the flare support sleeve. The support sleeve provides several key

functions:

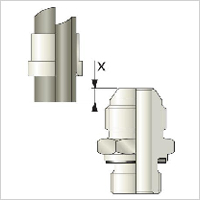

Study

the following example illustrating the options with an SAE -8 (1/2")

VE-LOCK fitting:

Study

the following example illustrating the options with an SAE -8 (1/2")

VE-LOCK fitting: |

|

|

|

|

JIC FLARE FITTINGS |

JIC MALE CONNECTOR |

JIC EQUAL ELBOW |

JIC EQUAL TEE |

|

|

|

|

|

JIC EQUAL UNION |

JIC NUT & FERRULE |

JIC HEX PLUG |

JIC BULKHEAD ELBOW |

|

|

||

|

JIC BULKHEAD UNION |

JIC SWIEVEL ELBOW |